Environmental Monitoring

Personnel Monitoring

This module is critical for ensuring that gowning procedures are effective, that personnel do not compromise clean zones, and that environmental monitoring programs are consistently upheld. Through simulation, trainees build the confidence and muscle memory needed to execute high-stakes sampling procedures in real-world operations.

Module Overview

Altoura’s Personnel Monitoring Procedures Training Module is an immersive, hands-on simulation designed to teach cleanroom operators how to properly monitor themselves for contamination in GMP-regulated environments. This essential module empowers learners to master contamination control by reinforcing self-inspection routines and sampling procedures that maintain the sterility of classified spaces.

In this simulation-based training, learners will follow a step-by-step protocol to conduct contact plate sampling on critical gowning sites, such as gloved hands, while practicing best practices for handling plates, labeling samples, and logging results. The experience emphasizes not just how to sample, but why each action is critical to preserving cleanroom integrity.

Trainees will interact with realistic cleanroom tools and environments, gaining real-time feedback as they prepare sampling materials, avoid common errors (like touching agar surfaces), and complete the monitoring process with precision and regulatory alignment.

SKILLS covered

- Understanding of Personnel Monitoring Principles

- Preparation and Equipment Readiness

- Correct Sampling Technique

- Sample Documentation and Traceability

- Proper Sample Storage

- Contamination Awareness and Prevention

Learning Objective

01

tore contact plates in designated incubators while preserving sample integrity

02

Prepare correctly by verifying sterility, PPE compliance, and tool readiness

03

Perform contact plate sampling using proper technique

04

Label each sample accurately for traceability and regulatory documentation

05

Enter all relevant details into a digital monitoring logbook

Explore more aseptic pre-built VR training modules for a GMP-ready workforce

ASEPTIC TECHINQUE & BEHAVIOUR

Hand Washing

Demonstrates GMP-compliant handwashing methods to maintain cleanroom sterility.

Module details

ASEPTIC TECHINQUE & BEHAVIOUR

Gowning

Covers Stage I and II gowning requirements and identify common gowning errors.

Module details

ASEPTIC TECHNIQUE & BEHAVIOUR

Unidirectional Airflow

Explains airflow types and best practices to prevent contamination in cleanroom environments.

Module details

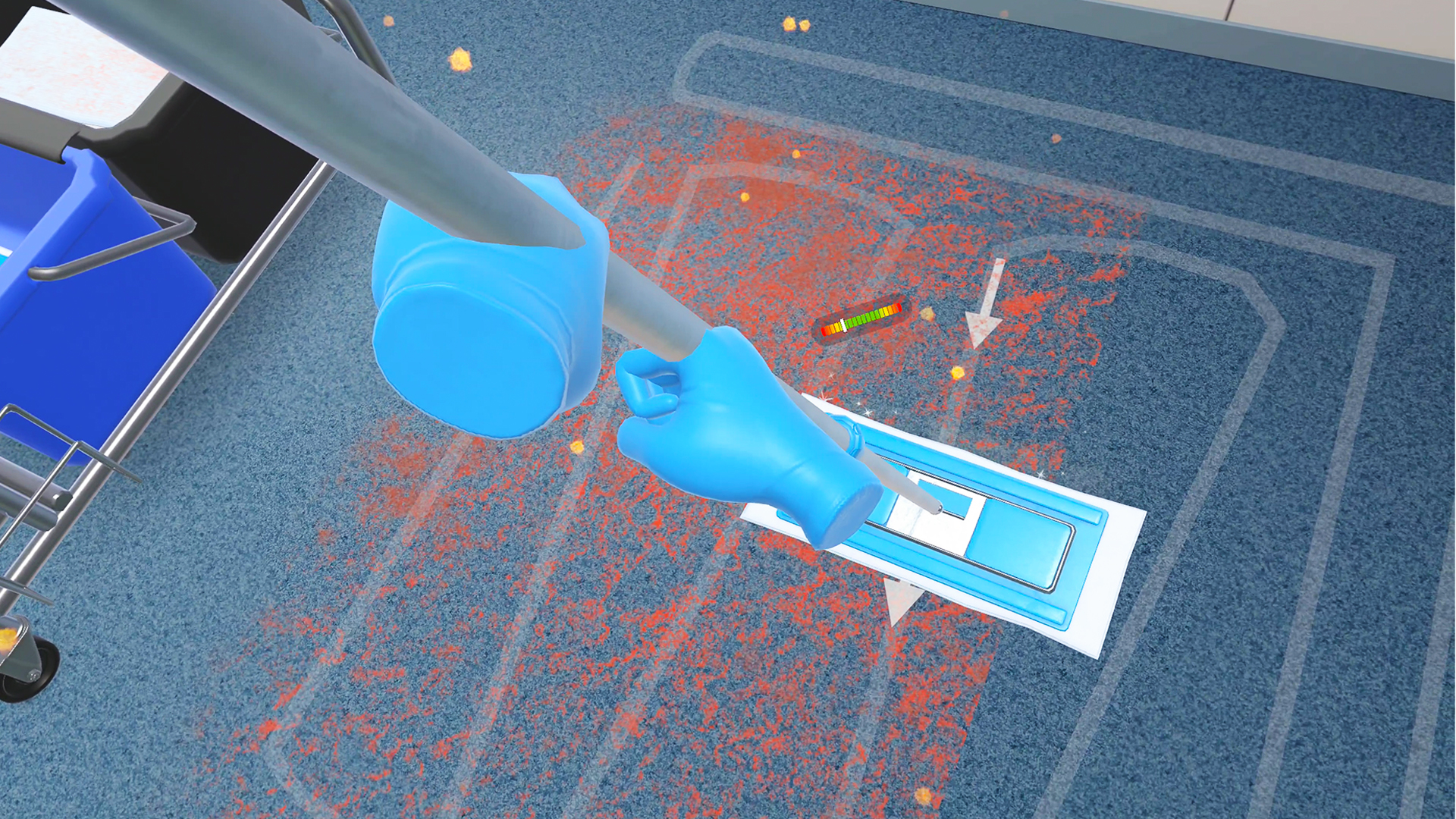

FACILITY CLEANING & DISINFECTION

Wall Cleaning Procedures

Covers proper cleaning methods for vertical surfaces in cleanrooms using SOPs and disinfectants.

Module details

FACILITY CLEANING & DISINFECTION

Floors Cleaning Procedures

Covers proper cleaning methods for horizontal surfaces in cleanrooms using SOPs and disinfectants.

Module details

FACILITY CLEANING & DISINFECTION

Surface Cleaning

Instructs on sterile wiping techniques and disinfectant use for cleanroom surfaces.

Module details

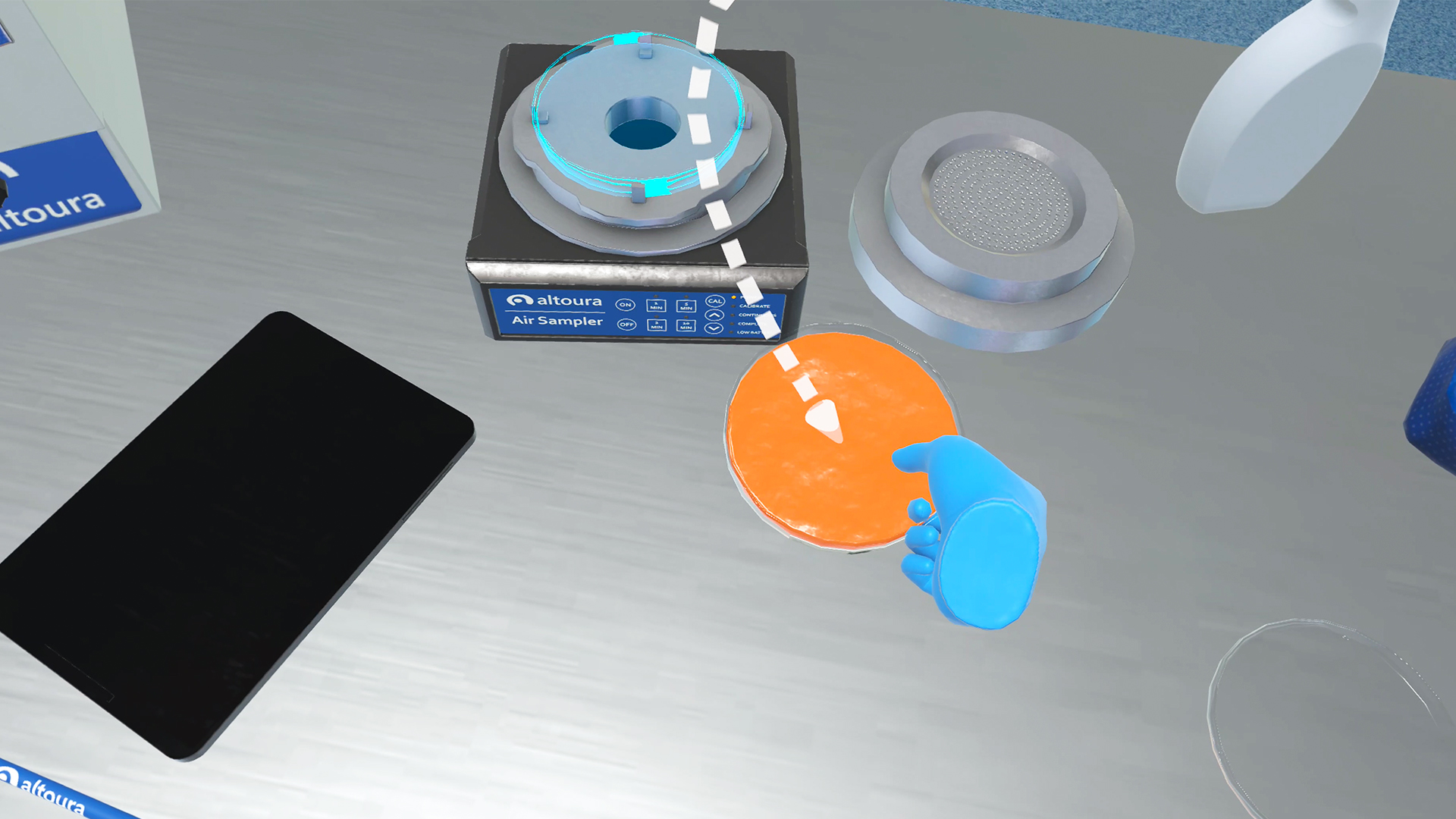

ENVIRONMENTAL MONITORING

Air Monitoring

Teaches air sampling, equipment use, and result analysis to maintain cleanroom compliance.

Module details

Get started with your personalized demo

Complete the form to get in touch with our sales team to see Altoura in action. We’ll show you how you can use Altoura to improve productivity, engage workers, and lower costs across your organization.

Please refer to the privacy policy for more information.